As the electrification of the vehicle world proceeds, hybrid vehicles are proving to be a sensible alternative to purely electric cars. The 48 V battery is the heart of a hybrid vehicle, representing the link between electrification and the internal combustion engine. Hybrid vehicles are differentiated by their level of hybridisation:

Board-to-Cable Connectors from Yamaichi – At the Heart of the Hybrid Vehicle

- Micro hybrid:

- Mild hybrid:

- Full hybrid (HEV):

- Plug-in hybrid (PHEV):

Micro hybrid:

In a micro hybrid, an electric motor acts as a starter motor and replaces the internal combustion engine when the vehicle is at a complete stop. With the help of this automatic start/stop and a recuperation capability – i.e. the ability to convert kinetic energy into storable electrical energy – energy flows back into the starter battery when the brake is actuated. As a result, the combustion engine can be switched off when idle. This is especially useful in city traffic and saves fuel.

Mild hybrid:

In the mild hybrid, an electric motor contributes approximately 10 kW (14 HP) to the driving performance of the vehicle. Mild hybrids also have the advantages of the micro hybrid (automatic start/stop and recuperation (regenerative braking)). Smaller combustion engines can be used to save fuel without sacrificing performance.

Full hybrid (HEV):

The next level is the full hybrid. This vehicle has an electric motor that propels the vehicle alone on starting and, up to a certain speed, during cruising. The electric motor also assumes the functions of the starter and the generator. However, there is no external battery charging here – unlike in the plug-in hybrid. Thus, a greater weight results from the required storage capacity of the battery and the electric motor and, consequently, the driving performance over long distances is negatively affected. There are two different variants of the full hybrid:

- In the serial full hybrid, an internal combustion engine drives a generator, which in turn feeds the electric motor. The internal combustion engine functions as an energy supplier and the electric motor alone provides the propulsion.

- The parallel hybrid can be driven with both types of propulsion – electrically and with an internal combustion engine – at the same time or only with an internal combustion engine.

Plug-in hybrid (PHEV):

The plug-in hybrid offers the advantage of having an externally rechargeable battery allowing it to cover greater distances purely electrically. This improves the electric motor performance and results in exceptionally high fuel savings.

Irrespective of the hybrid drive type, all vehicles have (or, with some providers, will in the future have) one component in common: the 48 V battery. In the mild hybrid, for example, the battery feeds the current to an electric motor, which can be connected, for example, to the belt drive of an internal combustion engine. The battery recharges itself through the recuperation technology. This energy, which would otherwise be lost as waste heat, can now be used. An AC-to-DC converter converts the voltage of the 48 V battery to the lower level of the 12 V on-board electrical system. Thus, on-board electrical systems can be supplied and additional torque can be provided to assist in propelling the vehicle. The 48 V electrical systems are therefore an important prerequisite for electric or partially electric vehicle propulsion.

And the technology is making great progress: for example, Bosch offers a 48 V battery that is the size of a shoebox and makes do without additional cooling systems. The crucial aspects of space requirements and additional weight are thus kept as low as possible.

Designed for battery applications

The trend in hybrid technology is promising. Bosch estimates that between 2020 and 2025 the share of passenger cars and light commercial vehicles with 48 V systems sold worldwide will rise from 5 to 20 per cent.

But which connector technology, besides the typical power transmitters, will be used here? Connectors for the thermal management sensors, for example, need to be especially easy to handle during assembly. They also need a locking mechanism that ensures a secure connection for the duration of their estimated 15-year life.

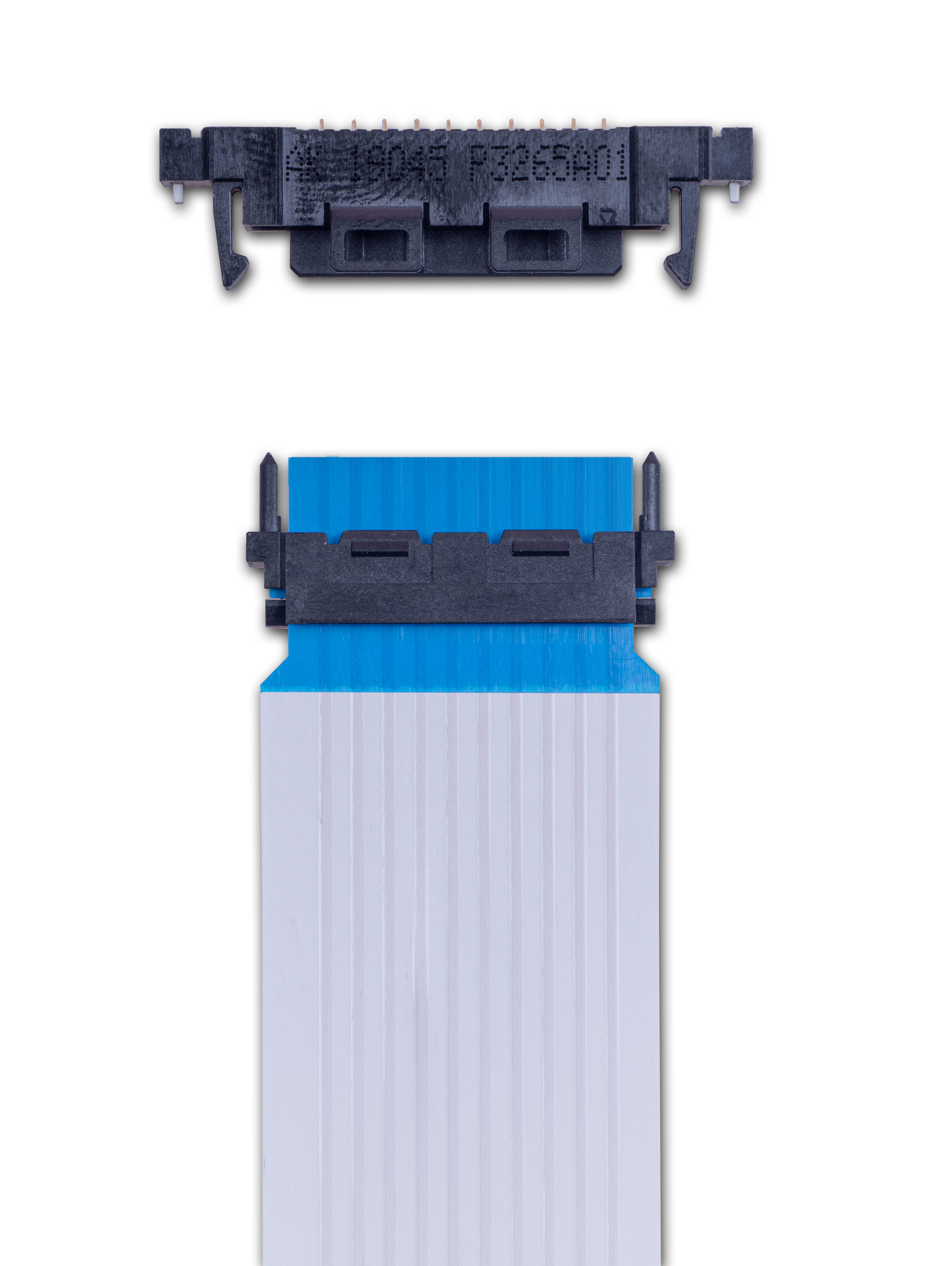

This is where Yamaichi comes in with the new Y-Lock series V3. Developed for battery applications, the system combines robust locking with high process reliability during assembly and in operation.

The core technology is the Pullforce system of the Y-Lock. Here, the flexible flat cable (FFC) or the flexible printed circuit (FPC) is inserted into the connector with the help of an assembled stiffener. It then automatically engages in two stages, first via side latches and in the next step via a front lock. Thanks to the guide pins on the system, blind connection is also possible. This blind mating property is especially advantageous for hard-to-reach applications or in tight spaces. Disconnecting is accomplished simply by pulling out the FFC/FPC – no mechanical actuation of the connector is required. Depending on the pitch (1 mm or 2 mm), between 0.5 A and 1 A can be transmitted.

Yamaichi currently offers variants with 10 or 20 pins and a 90° design.

Further designs of the Y-Lock V3 are already being planned. The connector system is qualified for the automotive sector based on LV214. If an FFC is used, Yamaichi offers the complete system, meaning the PCB connector and the FFC manufactured in-house and including the assembled stiffener.

Yamaichi produces both the FFCs and the stiffeners at the Frankfurt (Oder) location, where lamination, punching and folding are carried out on modern production lines. The company can also implement specific customer requirements such as special lengths or pre-folds.

Author: Daniela Pallas

Product Manager Connector Solutions