Innovative Designs for our European Customers

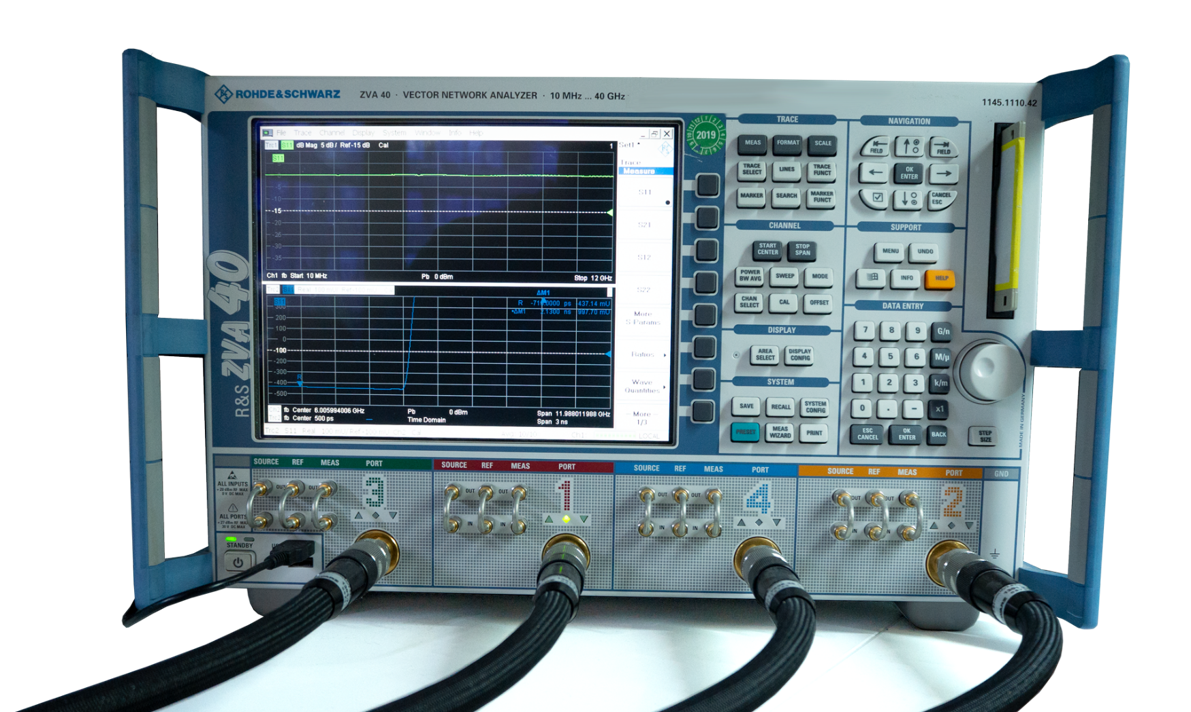

Having two Design Centers in Munich and Sousse, Tunisia, YAMAICHI ELECTRONICS is able to quickly react to market challenges and individual customer requirements in Europe. About 100 highly trained engineers at both sides work in the field of mechanics and electrical engineering. By creating more than 400 new designs every year YAMAICHI ELECTRONICS shows its innovative power.

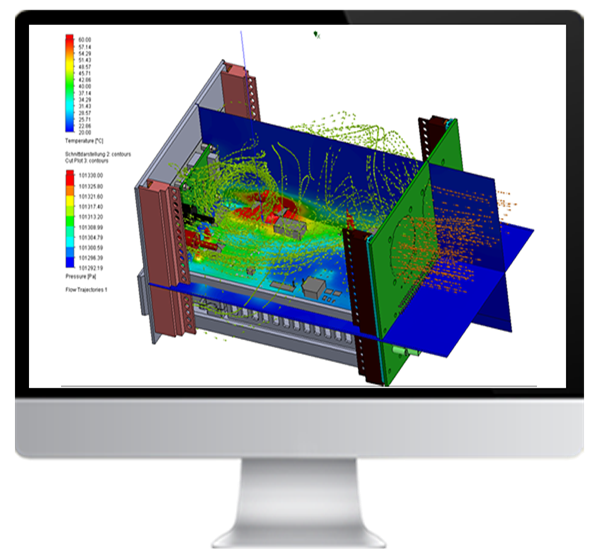

The most modern technologies are available for the realization from product idea to qualified mass production. We are aspired to further develop and contiunously improve technologies that meet the needs of our customers and offer them a competitive advantage in their respective industries.