Today, classic connection technology is undergoing fundamental changes. With the trend towards miniaturisation, connectors are also becoming smaller and smaller. Nevertheless, they should remain robust and withstand more and more mating cycles. This applies to the components in electronic systems for industrial electronics and consumer electronics as well as to devices for communication, medical or traffic technology.

Today, connectors must transmit energy, signals and as much data as possible. High-speed data rates in the range of Gbit/s require sophisticated RF concepts. For this, the user needs powerful and flexible, application-specific and, above all, compact connection solutions. For device manufacturers and users, properties such as reliability, availability and cost-effectiveness as well as smooth assembly are particularly important.

In electronic systems in all industries, connectors are often complex components with different electrical and mechanical environmental requirements. According to the application environments, the connection technology then also requires different designs and complexity.

Manufacturers are responding to new markets and applications such as Industry 4.0 with the accelerated expansion of multi-version product families. Connection technology specialist Yamaichi Electronics combines different technologies and is successively developing new versions based on the experience of the Y-Circ P push-pull connector series.

In the meantime, the company has launched an extensive range of push-pull connectors. Manufactured in Germany, the circular connectors with push-pull locking mechanism offer cost and many other advantages, as they save material and space and are easy to assemble.

Waterproof Circular Connectors for High Mating Cycles

Miniaturisation saves Costs, Space and Assembly Effort

The Y-Circ P series, whose name stands for Circular Connector Push-Pull, offers advantages through miniaturisation. It is pluggable to existing series on the market. Depending on the connector type, the connector is lighter and up to 20% shorter than comparable circular connectors on the market. This means that shorter device sockets can be used, which provides more space in the customer's application.

The optimised length makes the connector lighter and less susceptible to vibrations. The push-pull locking mechanism allows easy mating and unmating by pulling on the connector housing.

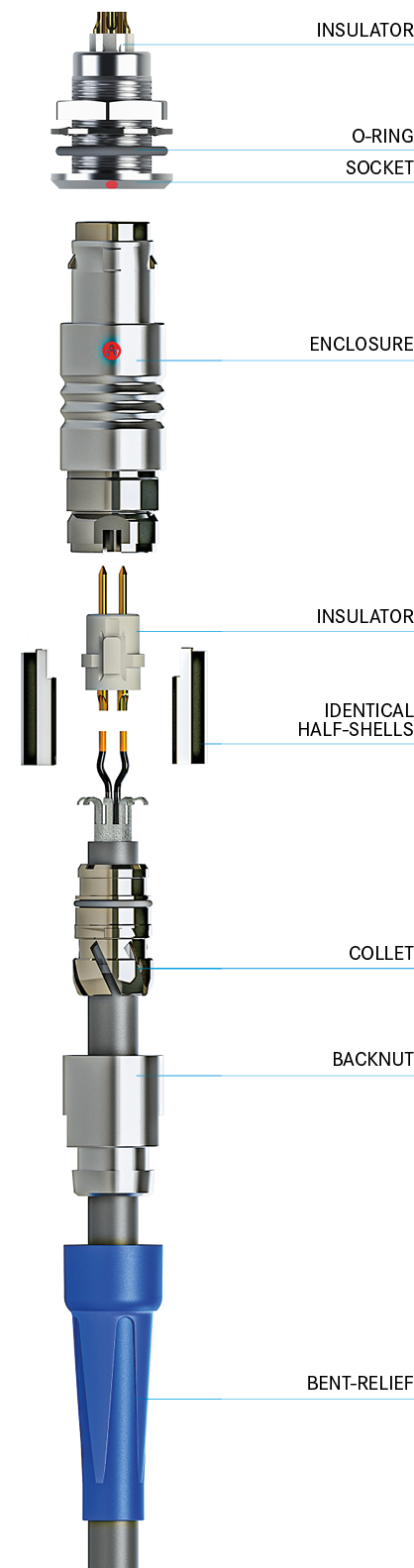

High-quality contacts guarantee at least 5000 mating cycles. In addition, the design of the shield contact has been optimised. All half shells are identically designed and can therefore no longer be confused during assembly. This significantly simplifies the assembly of the connector and reduces the assembly effort.

The robust, chrome-plated metal housing has a high value, which is why the connector is also predestined for use on devices with high optical demands. Thanks to the machined contacts, both secure data transmission and high currents are no problem.

The first product in the group was the B series. It has a degree of protection of IP50 and is offered in many combinations. The connectors of this series are available in sizes 9, 12, 15 and 18, each of which the customer can have equipped with a different number of contacts.

Based on the B version, the manufacturer developed a waterproof connector: the T-series opens up new areas of application - wherever dust and water or all forms of moisture occur and can impair the functionality of cables and connectors.

These include harsh system environments in mechanical engineering, in IT and robot systems as well as in the automotive industry and in the aircraft industry. The applications range from underwater use to medical technology; camera systems and control systems in outdoor areas are also areas of application.

The T-series connectors offer many advantages over comparable connectors. Miniaturisation was also the focus for this version. The challenge for the engineers during development was to integrate the locking mechanism and IP68 protection into the size of the B series. In addition, the insulators of the B series were to be reused.

Optimised Cable Sealing Simplifies Installation

The most important feature is the optimised cable seal. For this purpose, the developers realised a compact sealing concept, with which the waterproof connector can be assembled much more robustly, quickly and with less risk. The seal to the cable was reduced to a single, specially sealing collet - standard connectors on the market contain up to three parts. This principle simplifies and speeds up assembly enormously. Whereas with other connectors several parts have to be assembled, with the T-series only one part has to be mounted. On the one hand, this is much easier and, on the other hand, minimises the risk of seal damage.

In addition, the cable shielding can be cut to length with very high tolerances. This makes it almost impossible for shield wires to protrude into the sealing area and impair the sealing effect. The one-piece collet makes the assembly so secure that there is no need to worry about anything shifting during assembly and thus no longer guaranteeing an optimal seal.

Locking by Means of Long Locking Hooks increases Mating Cycles

The second key point of the new connector concept is the optimised locking system. Due to the longer locking hooks, high mating cycles can also be reliably achieved for this series. As a result, the same codings as for the B-series are also possible.

The design allows waterproofing up to at least IP68, which at Yamaichi means permanent submersion for 48h at a water depth of 1m.

In addition to the standard pole patterns, special pole patterns for high-speed data transmission are also available. Thus, data transmission rates of up to 10 Gbit/s are possible, which also offer sufficient reserves for future data transmission tasks in industry and data networking.

The versions of the T-series are available in all sizes (9, 12, 15 and 18) as cable plugs and cable sockets as well as device sockets in various designs.

Made in Germany

All push-pull connectors are manufactured by the connector specialist in Germany. The company's own production facility offers a high level of vertical integration. The employees have years of experience in connector production and cable assembly. This enables fast and flexible production for European customers. "Made in Germany" is also the company's customer-oriented cable assembly at the Frankfurt (Oder) site.

Customers can thus obtain complete cable assemblies from a single source in a short time, in addition to individual products. In addition to the various push-pull connectors of the Y-Circ P series, the company's own M12 circular connectors of the Y-Circ M series as well as special industrial RJ45 connectors of the Y-Con series are also processed in cable assemblies. On customer request, the cable assemblies with Yamaichi connectors can also be combined with purchased components.

As the Y-Circ-P product family has quickly established itself on the market, Yamaichi will continue to successively expand the product range.

The product configurator provides an overview of the diverse product versions and the possibility to configure the suitable connector yourself: configurator.yamaichi.de

Author: Matthias Schuster

Product Manager Connector Solutions